Author: Daniel G. Teleoaca – Maritime Chief Engineer

Author: Daniel G. Teleoaca – Maritime Chief Engineer

In an era where environmental concerns are at the forefront of global discussions, the maritime industry faces increasing pressure to reduce its ecological footprint. One of the most significant challenges in this sector is the reduction of nitrogen oxide (NOx) emissions from vessel engines. Enter Selective Catalytic Reduction (SCR), a groundbreaking technology that’s transforming the way ships manage their exhaust emissions.

SCR systems have emerged as a powerful solution for vessel operators seeking to comply with stringent international regulations while maintaining operational efficiency. This advanced technology uses a chemical reaction to convert harmful NOx emissions into harmless nitrogen and water vapor, dramatically reducing the environmental impact of maritime operation.

As we delve deeper into the world of SCR systems for vessel engines, we’ll explore their working principles, benefits, challenges, and the future of this technology in the maritime industry. Whether you’re a seasoned maritime professional or simply curious about environmental technologies, this comprehensive guide will provide valuable insights into how SCR is shaping the future of cleaner seas.

How SCR Works in Vessel Engines

Selective Catalytic Reduction is an advanced emissions control technology that plays a crucial role in reducing NOx emissions from vessel engines. The process involves several key steps:

Injection of Reducing Agent: A liquid-reductant agent, typically automotive-grade urea (also known as Diesel Exhaust Fluid or DEF), is injected into the exhaust stream of the diesel engine.

Chemical Reaction: The heat of the exhaust breaks down the urea into ammonia (NH3). This ammonia then reacts with the NOx in the presence of a catalyst.

Catalytic Conversion: The exhaust gas, now mixed with ammonia, passes through a special catalyst. Here, the NOx is converted into nitrogen (N2) and water vapor (H2O).

Emission of Harmless Substances: The resulting nitrogen and water vapor, both naturally occurring components of the air we breathe, are then expelled through the vessel’s exhaust system.

SCR systems can be classified into two types based on their configuration:

High-Pressure SCR: Placed before the turbocharger, this type maintains a high exhaust gas temperature (300-400°C) and can run on Heavy Fuel Oil.

Low-Pressure SCR: Located between the turbocharger and the exhaust gas boiler, this type operates at lower pressures.

The effectiveness of SCR systems is remarkable, with the potential to reduce NOx emissions by up to 90%. This level of reduction is crucial for meeting the International Maritime Organization’s (IMO) Tier III NOx standards, which apply to ships constructed on or after January 1, 2016, operating in designated emission control areas.

Benefits of SCR in Maritime Applications

The implementation of SCR systems in vessel engines offers numerous advantages, making it an attractive option for shipowners and operators:

Significant NOx Reduction: SCR technology can reduce NOx emissions by up to 90%, helping vessels meet the most stringent environmental regulations.

Fuel Efficiency: Unlike some other emissions reduction technologies, SCR allows for engine optimization for fuel efficiency. Some SCR-equipped truck operators have reported fuel economy gains of 3-5%.

Versatility: SCR systems can be applied to various types of vessels, including cargo ships, ferries, tugboats, and offshore platforms.

Simultaneous Reduction of Multiple Pollutants: While primarily targeting NOx, SCR systems can also reduce hydrocarbon (HC) and carbon monoxide (CO) emissions by 50-90%, and particulate matter (PM) by 30-50%.

Compatibility with High Sulfur Fuels: Some SCR systems, particularly high-pressure configurations, can operate effectively with high sulfur content fuels.

Flexibility in Engine Design: SCR technology allows engine manufacturers to focus on improving combustion efficiency and power output, as the NOx reduction occurs post-combustion.

Proven Technology: SCR has been used successfully in stationary applications for decades and has been adapted effectively for maritime use.

Real-world examples demonstrate these benefits. For instance, an SCR system implemented on an offshore platform off the west coast of Norway was designed for 8 main engines, each with approximately 5,800 kW. This system can handle a urea quantity of 825 l/h at about 12 bar, effectively reducing NOx to meet Tier III standards even under full-load conditions.

Challenges and Considerations

While SCR technology offers significant benefits, there are several challenges and considerations that shipowners and operators must address:

Temperature Requirements: SCR systems operate most effectively within a specific temperature range, typically 250-400°C. Maintaining this temperature can be challenging, especially during low-load operations or when ships are in port. Solution: Engine manufacturers have introduced operational features to ensure appropriate exhaust gas temperatures are met at low loads. Some have demonstrated that SCR can meet Tier III standards even at 10% load with only a minimal fuel penalty.

Ammonia Slip: There’s a potential for unreacted ammonia to be released, which can be harmful to the environment. Solution: Careful control of the urea injection rate and continuous monitoring can keep ammonia slip below 10 ppm, even at low loads.

Installation Space: SCR systems require additional space in the engine room, which can be a challenge for some vessel designs. Solution: Manufacturers are developing more compact SCR designs. For example, a study on compact design in marine urea-SCR systems showed that changing the shape of the mixing chamber from square to circular could increase NO reduction performance by 84.5% while maintaining a similar pressure drop to conventional models.

Initial Costs: The installation of an SCR system represents a significant upfront investment. Solution: While initial costs are high, the long-term benefits in terms of fuel efficiency and compliance with regulations can offset these expenses over time.

Urea Consumption and Storage: SCR systems require a continuous supply of urea, which necessitates additional storage and handling considerations on board. Solution: Advanced SCR control systems can optimize urea consumption, and some designs align SCR service periods with engine overhaul intervals to minimize operational disruptions.

Catalyst Durability: The catalyst can be affected by sulfur in the fuel, potentially reducing its effectiveness over time. Solution: The use of sulfur-resistant catalysts, such as vanadium-based catalysts, can mitigate this issue.

The Future of SCR in Maritime Applications

As environmental regulations continue to tighten and the maritime industry seeks more sustainable operations, SCR technology is poised to play an increasingly important role. Here are some key trends and developments to watch:

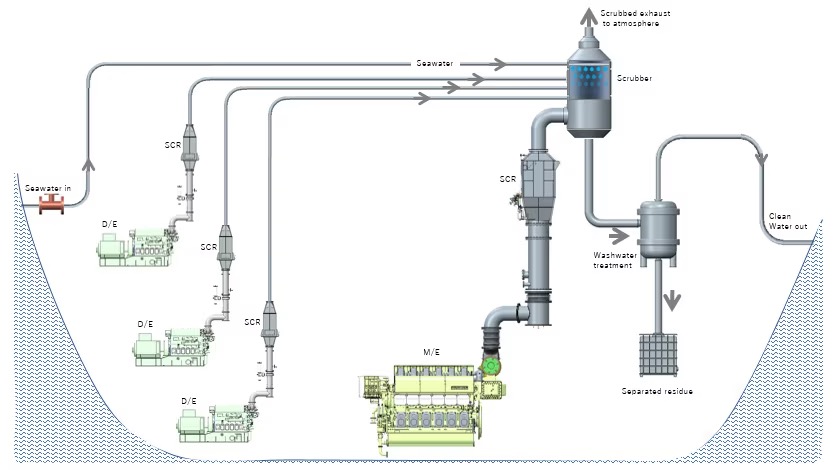

Integration with Other Technologies: SCR systems are being combined with other emissions reduction technologies, such as exhaust gas recirculation (EGR) and scrubbers, to create comprehensive emissions control solutions.

Advancements in Catalyst Technology: Ongoing research is focused on developing more efficient and durable catalysts that can operate effectively across a wider range of conditions.

Smart SCR Systems: The integration of artificial intelligence and machine learning is leading to more intelligent SCR systems that can optimize performance based on real-time operating conditions.

Compact Designs: As space remains a premium on vessels, manufacturers are working on more compact SCR designs that maintain high efficiency while reducing the system’s footprint.

Alternative Reducing Agents: While urea is currently the most common reducing agent, research is ongoing into alternative substances that could offer improved performance or easier handling.

Wider Adoption: As more stringent emissions regulations come into force globally, SCR systems are likely to become standard equipment on a broader range of vessels.

In conclusion, Selective Catalytic Reduction (SCR) technology represents a significant leap forward in the maritime industry’s efforts to reduce harmful emissions and meet increasingly stringent environmental regulations. By effectively reducing NOx emissions by up to 90%, SCR systems are playing a crucial role in making maritime transportation more sustainable.

Key points to consider:

- SCR technology offers a proven, effective solution for NOx reduction without significantly compromising engine performance or fuel efficiency.

- The versatility of SCR systems allows for their application across various vessel types and engine configurations.

- While challenges exist, such as temperature management and ammonia slip, ongoing technological advancements are addressing these issues.

- The initial investment in SCR technology can be offset by long-term benefits, including compliance with regulations and potential fuel savings.

Learning takeaways:

- Understanding SCR technology is crucial for maritime professionals as it becomes more prevalent in the industry.

- The successful implementation of SCR systems requires careful consideration of vessel-specific factors and operational profiles.

- Ongoing maintenance and monitoring are essential to ensure optimal SCR performance and longevity.

- As environmental regulations evolve, SCR technology is likely to play an increasingly important role in maritime emissions control strategies.

- As we look to the future, SCR technology will undoubtedly continue to evolve, offering even more efficient and effective solutions for reducing maritime emissions. By embracing this technology, the maritime industry is taking a significant step towards a cleaner, more sustainable future for our oceans and our planet.

Learn more by following the link about “Marine MARPOL Convention on Air”.

Find more by following the link about “Marine Clean Air Act and Inspections”.

If you have any questions regarding above, please feel free to use our existing forum Seafarer’s World, Telegram Chief Engineer’s Log Chat or Instagram and will try to answer to all your queries. You can use the feedback button as well!

If you like my posts, please don’t forget to press Like and Share. You can also Subscribe to this blog and you will be informed every time when a new article is published.

One Comment